At Fabrication Services, we specialize in a wide range of services, including heavy metal fabrication, plate rolling services, sheet metal rolling, and sheet metal forming. Our facility is equipped with advanced machinery and staffed by a team of skilled professionals who are capable of handling a variety of materials and complex fabrication tasks. With a dedicated approach to every project, we guarantee top-quality outcomes on time, every time.

Heavy Metal Fabrication

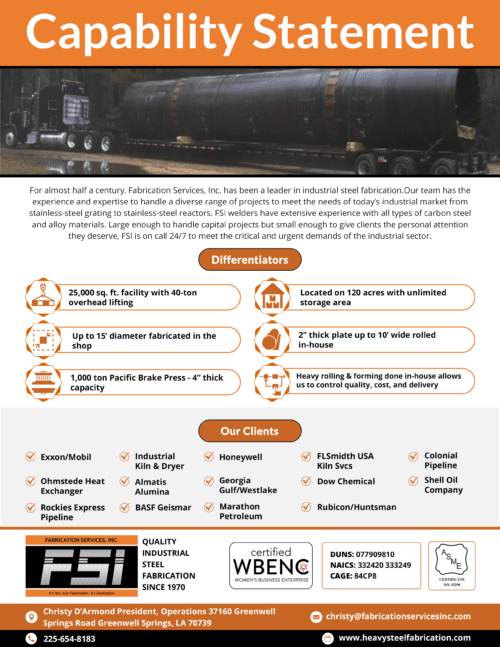

Heavy metal fabrication is one of the core services we offer. Our team has the expertise to work with large and dense materials, providing the strength and durability needed for demanding projects. Using equipment like the 1,000-ton Pacific Brake Press and 40-ton overhead lifting capabilities, we can fabricate components such as pressure vessels, tanks, and shells. This expertise has allowed us to partner with industry giants like Exxon/Mobil, Honeywell, and BASF, completing projects that require precise and reliable fabrication.

Plate Rolling Services

FSI excels in plate rolling services, where we roll plates up to 2” thick and 10’ wide in-house. This capability is crucial for industries requiring cylindrical components, such as vessel shells, tank shells, and kiln shells. The plate rolling process guarantees that each product is formed to precise specifications, meeting the highest standards of quality and accuracy. Our in-house capabilities help keep projects on track, making sure that we can deliver within tight timelines while controlling costs and quality.

Sheet Metal Rolling

Our sheet metal rolling service plays an important role in transforming raw metal sheets into cylindrical shapes. This service is perfect for producing components used in a wide variety of industries, from construction equipment to HVAC systems. We handle both hot rolling and cold rolling processes. Hot rolling, which involves heating the metal, allows us to manipulate the material with less force, while cold rolling requires more pressure but results in a stronger, more durable product. Our team utilizes advanced rolling machines to meet each client’s specific needs, having a high level of precision.

Sheet Metal Forming

Sheet metal forming is a key service at FSI. We utilize a variety of techniques to shape metal, including bending, punching, and pressing. These methods are critical for producing components like structural pieces, brackets, and parts for the automotive and construction industries. Sheet metal forming is cost-effective and efficient, which makes it ideal for large production runs or custom components. Our skilled craftsmen make sure that each part is created to exact specifications, resulting in components that are both durable and reliable.

Why Choose Fabrication Services, Inc.?

With a 35,000-square-foot facility, we have the space and equipment to handle both small and large-scale projects. All work is performed in-house, allowing us to maintain complete control over quality and delivery schedules. With 24/7 customer support, we are always available to address any urgent needs.

For over five decades, FSI has built lasting relationships with industry leaders in sectors like oil and gas, aerospace, and chemical processing. Our ability to handle projects efficiently, with exceptional results, has made us a trusted partner to companies like Shell Oil, Marathon Petroleum, and Honeywell.

If you need a reliable partner for your next heavy metal fabrication project, look no further than Fabrication Services, Inc. Contact us today to discuss your needs and learn how we can help bring your project to life.